Our capabilities

Always growing stronger

-

Transport and freight

Road freight

Rail freight

Fleet and equipment

Intermodal

Cold chain

Home delivery

Bulk liquids

Bulk haulage

Production support logistics

Dangerous goods

Cross border capabilities

Coastal freight -

Warehousing and distribution

Modern warehousing

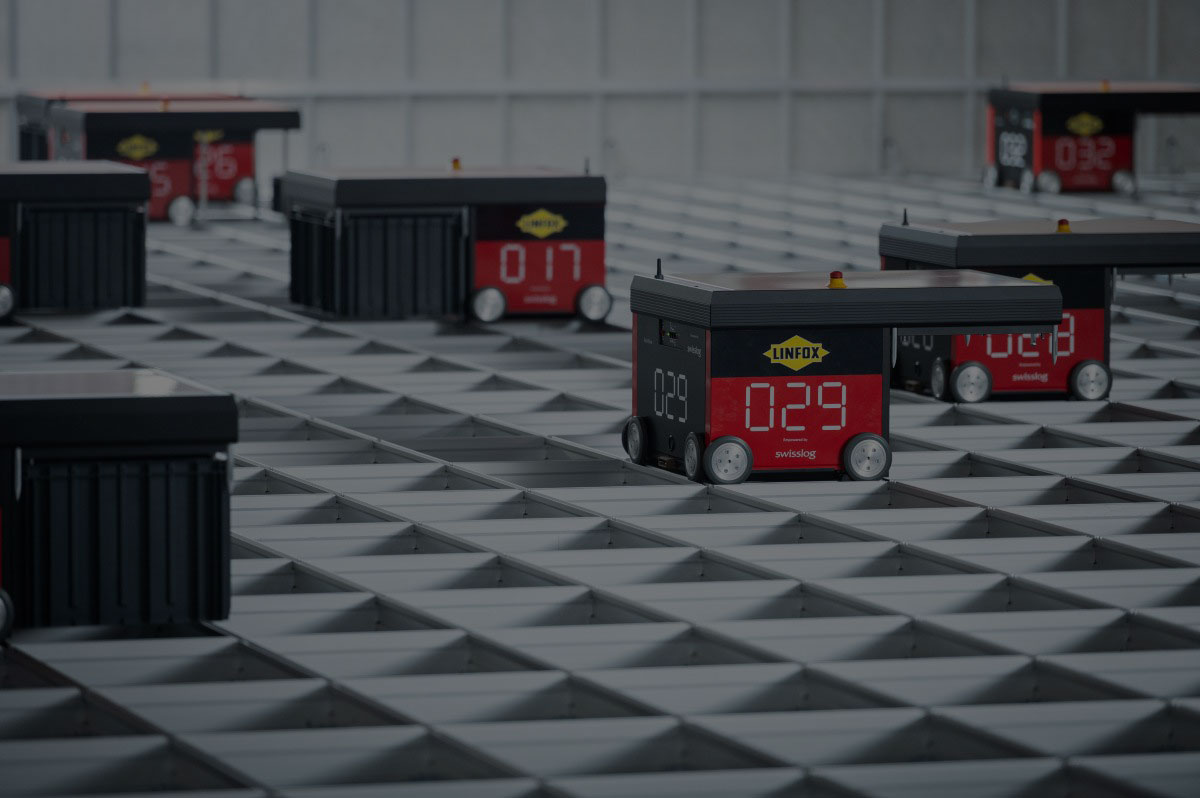

Automated distribution centres

Distribution

Shared operations

Remote logistics

Dangerous goods storage -

Smarter supply chains

Smarter transport

Smarter warehousing

Connecting customers

Cybersecurity

Network design and analytics

Continuous improvement

High security network

Leading the way

A commitment to be safer underpins our work

Moving goods in a safe and compliant way is paramount to protecting our people and the communities in which we operate.

Safety, health and wellbeing

Training programs

Latest news

How we’re leading in logistics

Solutions Magazine

Driven by purpose

Linfox’s new Adelaide rail freight terminal facility is now alive with activity after opening next to the city’s interstate rail line.

Linfox has earned the coveted Climate Active carbon neutral building certification for its Willawong, QLD cross-functional facility.

View Online Edition

View All Editions

See how we’re improving supply chains everyday

Experience

From one man and a truck to a sophisticated multinational operation, the Linfox story is one of extraordinary achievements.

Backed by 65 years of expertise, we do much more than deliver goods.

Sustainability

Environmental outcomes are not just good for our planet, they’re good for business.

As we work towards a more sustainable transport and logistics industry, the next decade will see big changes in the way we operate our fleet and facilities.

24,000+

People

450 Million

KMs travelled annually

4.8M

m2 Warehousing